Offres d’emploi

-

OCA at SEPEM Industries in Angers 2025

OCA at SEPEM Industries in Angers 2025

The OCA team is delighted to be participating in the next edition of SEPEM Industries d'Angers, which will be held on October 7, 8, and 9, 2025. This trade show, a key event for industrial players in the Pays-de-la-Loire region, is the ideal opportunity to discuss your projects and discover the latest innovations in the sector.

What is SEPEM Industries in Angers?

SEPEM Industries in Angers is a regional trade show dedicated to industrial solutions for all production sectors. It brings together more than 450 exhibitors and welcomes thousands of professional visitors who come to find concrete answers to their maintenance, production, safety, and industrial environment issues. With 11,000 m² of exhibition space, it is a key event for manufacturers in western France who want to learn, innovate, and develop their network.

The OCA team at SEPEM Toulouse 2024

Register for the event for free

Come and discover our overhead handling solutions at the OCA stand

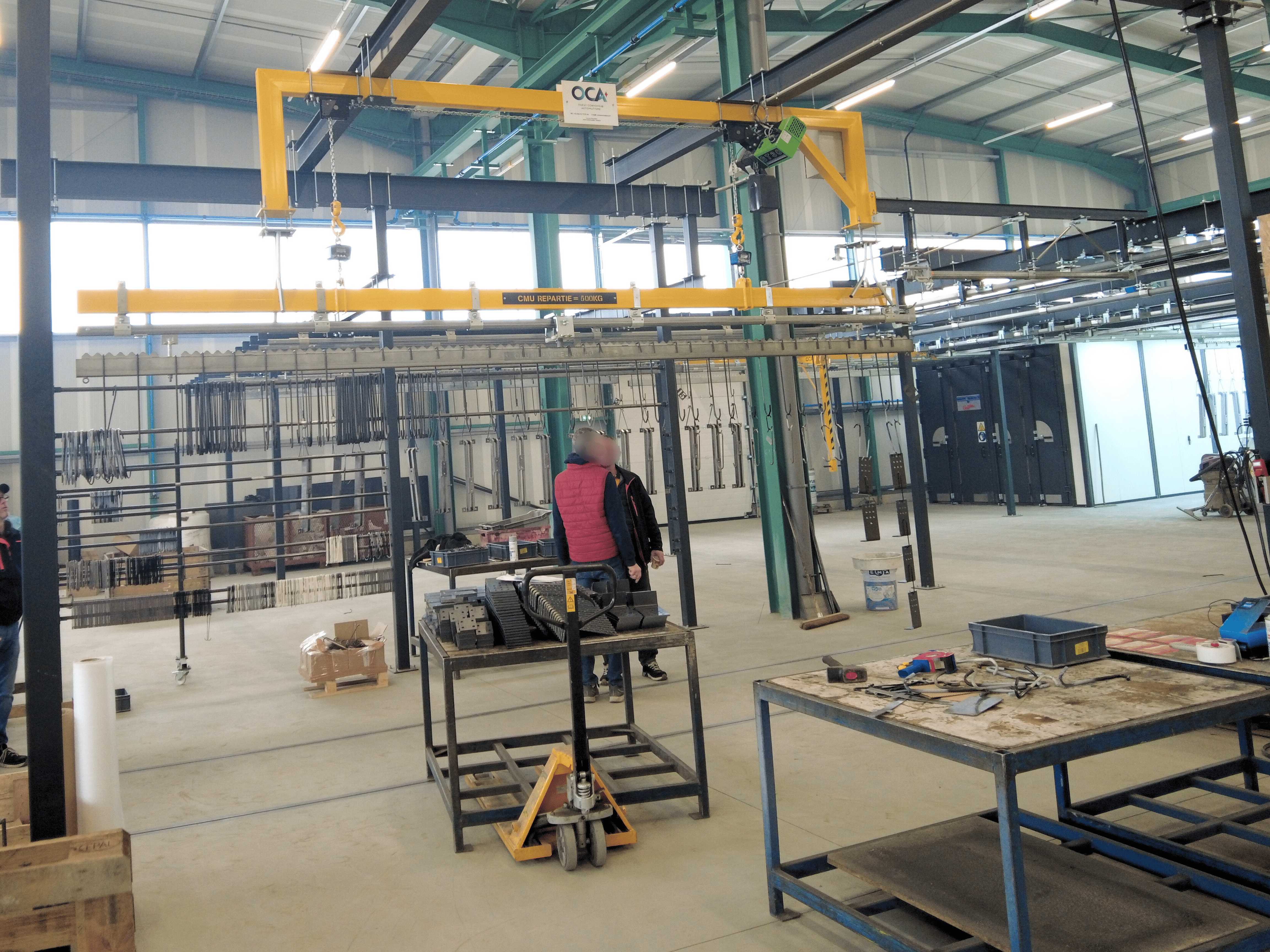

Visit us at stand H41, where our team will be on hand to advise you and assist you with your overhead handling needs. Transport, transfer, or storage of loads: for 44 years, we have been offering customized, high-performance conveyor solutions tailored to your production constraints.

Our systems also aim to improve the ergonomics of your employees' work, for simpler, faster, and safer operations.

Take advantage of this trade show to discover our equipment in operation and talk to our experts.

Practical information

▪️Date: October 7, 8, and 9, 2025

▪️Hours: 8:30 a.m. to 5:00 p.m.

▪️Location: PARC DES EXPOSITIONS – DESTINATION ANGERS – Route de Paris – 49480 Saint Sylvain-d'Anjou

▪️Free registration via this link : https://angers.sepem-industries.com/registration/registration

-

Case study: Integration of a paint line for total autonomy

Case study: Integration of a paint line for total autonomy

Context and customer requirements

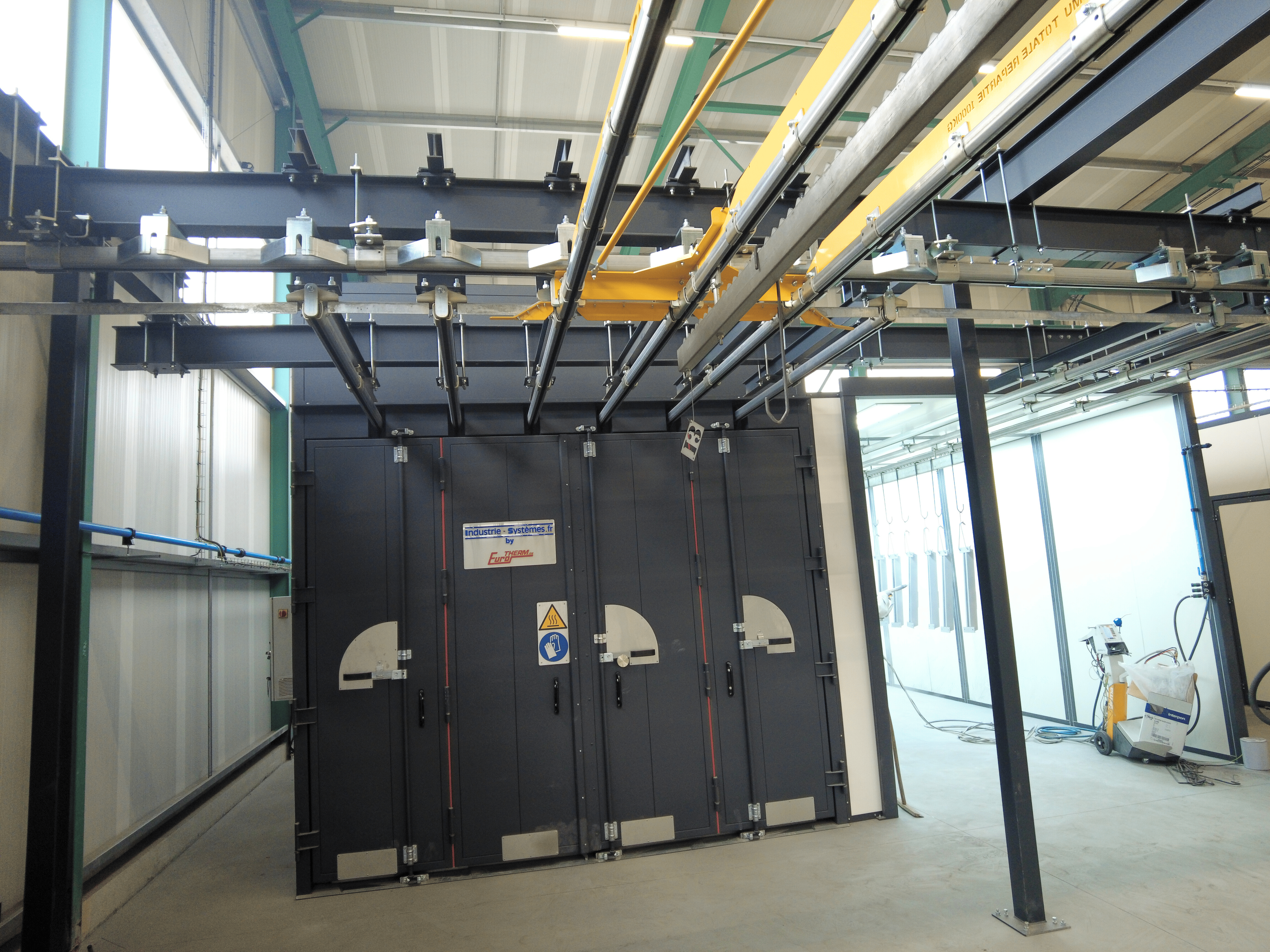

Our customer wanted to integrate a paint line within its production site in order to gain greater autonomy. The aim was to reduce the costs and lead times associated with subcontracting, while optimizing the manufacturing process.

Technical constraints

The overhead handling system had to be able to transport loads of up to 500 kg per spreader bar, and to accommodate parts of varying dimensions: from 400 mm to 1500 mm wide, with a maximum length of 7000 mm. In addition, the installation had to allow for future expansion with three additional storage rails.

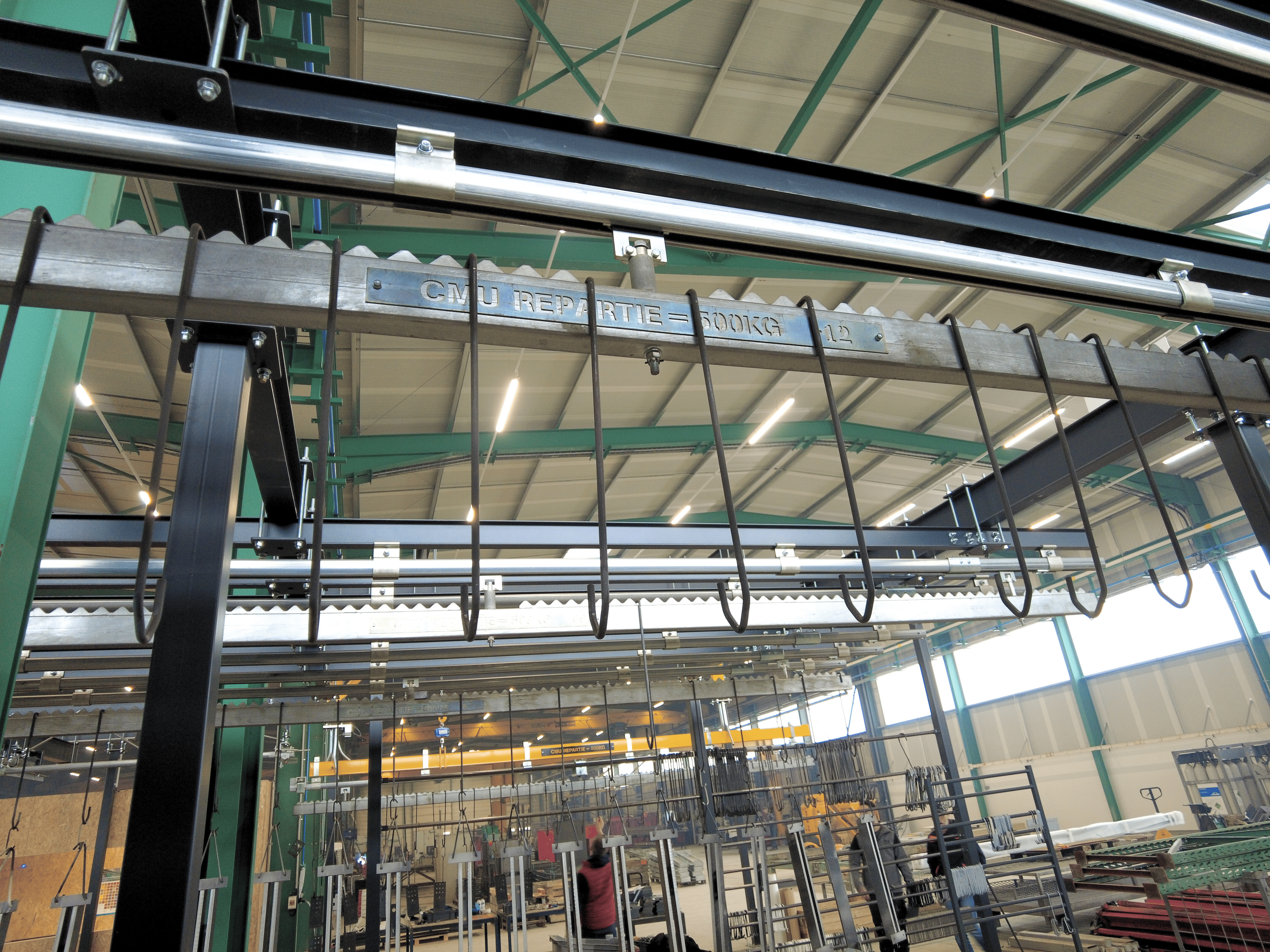

Lifting beam for transporting parts to be surface-treated.

The handling solution proposed by OCA

To meet these requirements, OCA designed and installed an optimized Telesto conveyor line comprising :

- A loading station equipped with a lifting station to facilitate loading and improve ergonomics for operators, thus reducing musculoskeletal disorders (MSD).

- One rail in the automatic shot-blasting machine for part pre-treatment.

- Three rails in the powder booth to ensure even application.

- Six rails in the baking oven to optimize paint curing.

- Six rails in front of the paint booth for smooth production flow.

- Six cooling rails for rapid drying before handling.

The results

Thanks to this new installation, our customer is now completely autonomous in his painting operations. He has been able to make significant savings by eliminating transport costs and saving precious time - between 15 and 20 minutes per production cycle.

With this modular set-up, he also has scope for future expansion of his paint shop.

The OCA team is proud to have supported this customer in his production modernization and optimization project!

Are you a surface treatment manufacturer looking to boost your productivity?

-

OCA takes part in the Full Robotics 2025 event organized by Proxinnov

OCA takes part in the Full Robotics 2025

event organized by Proxinnov

We will be present at the 5ᵉ edition of Full Robotics, the B2B event dedicated to industrial robotics organized by Proxinnov, to be held on Thursday, June 12, 2025.

As every year, this unmissable event will bring together the major players in robotics and automation around a central theme: agile production. This approach, which aims to improve the flexibility and responsiveness of industrial processes, fully echoes the mission and solutions proposed by OCA.

An intelligent conveyor at the service of agile production

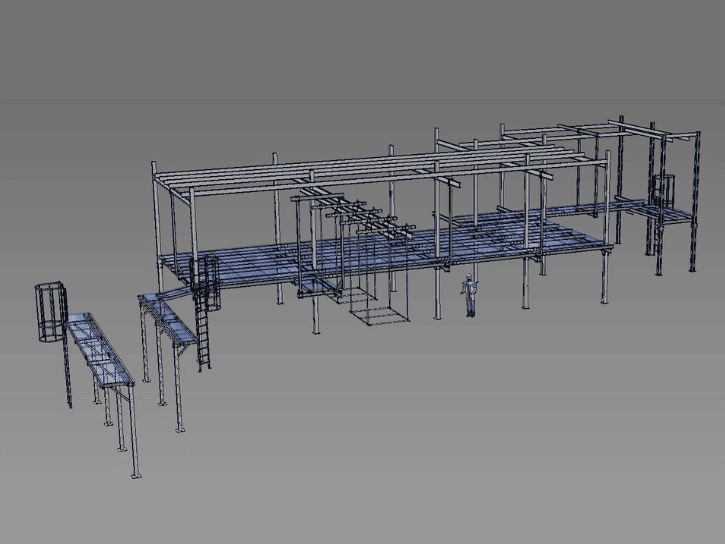

On this occasion, OCA will be exclusively presenting an intelligent conveyor for overhead flow processing. Designed for the automated transport of loads of up to 100 kg, this system enables the routing of parts between different workstations and production islands in an industrial environment.

This conveyor stands out for its ability to accumulate and trace loads, offering great flexibility in flow management. It fits perfectly into an agile production logic, facilitating rapid line reorganization and optimizing floor space thanks to overhead handling.

OCA intelligent conveyor for overhead flow processing

A rich program of innovationsThroughout the day, visitors will be able to attend:

- Live demonstrations of innovative robotic and automated solutions,

- Business meetings to exchange with exhibitors and develop their network,

- Conferences and round tables on production flexibility, feedback and the outlook for the robotics market.

List of the 38 exhibitors at Full Robotics 2025

Join us on June 12, 2025 at Proxinnov and explore the possibilities offered by intelligent aerial handling for ever more agile production.

I register for free to the event

Practical information

▪️Date: Thursday June 12, 2025

▪️Times: 8:30 a.m. to 4:00 p.m.

▪️Venue: 15 rue Jean Esswein, 85000 La Roche sur Yon

▪️Free registration by following this link : https://fullrobotics2025.eventbrite.fr -

Case study: Securing the sling storage area and improving responsiveness for an industrial laundry

Case study: Securing the sling storage area and improving responsiveness for an industrial laundry

Context

In industrial laundries, operator safety and efficient breakdown management are crucial issues. One of our recent collaborations highlighted these challenges. Our customer, an industrial laundry, was faced with a sling storage area, identified as dangerous for its teams. In addition to safety risks, the laundry needed better reactivity in the event of intervention on its slings, to minimize production stoppages.

Unsecured sling storage area, prior to OCA intervention

Proposed solution

After identifying the challenges faced by our customer, we carried out an in-depth audit of the soiled linen sorting area in order to propose a tailor-made solution. We redesigned and secured the workspace to eliminate risks, while deploying a rapid troubleshooting system to guarantee effective intervention in the event of a breakdown or malfunction.

Here are the actions taken:

1. Deployment of a security platform with a rapid recovery system

A security platform has been set up to ensure immediate intervention in the event of a breakdown. This enables equipment to be brought back into service quickly, reducing production interruptions and optimizing operational performance.2. Securing the high-risk area

The area has been redesigned to comply with the most stringent safety standards. This included installing protective devices, modernizing safety equipment and optimizing ergonomics to improve operators' working conditions.Secure platform designed and installed by OCA

The results: Safety, performance and responsiveness

Thanks to our intervention, the customer saw several immediate improvements:

- Optimal safety and risk reduction: The work area, now compliant with safety standards, offers a safer, more reliable environment for operators, with optimized risk management.

- Increased responsiveness: The new platform enables rapid intervention in the event of breakdown, ensuring maximum continuity of service.

A proactive approach to enhanced safety and productivityAt OCA, we know that when it comes to safety and maintenance, every minute counts. That's why we place responsiveness and security at the heart of our actions. We are always ready to listen to our customers, and do our utmost to offer them innovative, tailor-made solutions that enable them to work in the best possible conditions.

Are you an industrial laundry operator looking to improve

the safety and responsiveness of your facilities? -

OCA takes part in Global Industrie alongside Proxinnov!

OCA takes part in Global Industrie alongside Proxinnov!

The Global Industrie trade show is a must-attend event for manufacturers in search of innovation and performance. The event brings together key industry players, offering a unique opportunity to discover the latest technologies, exchange ideas with experts and forge strategic partnerships. Whether to optimize production or anticipate market trends, Global Industrie is the ideal place to meet the challenges of the industry of the future and stay competitive.

OCA breaks new ground at Global Industrie

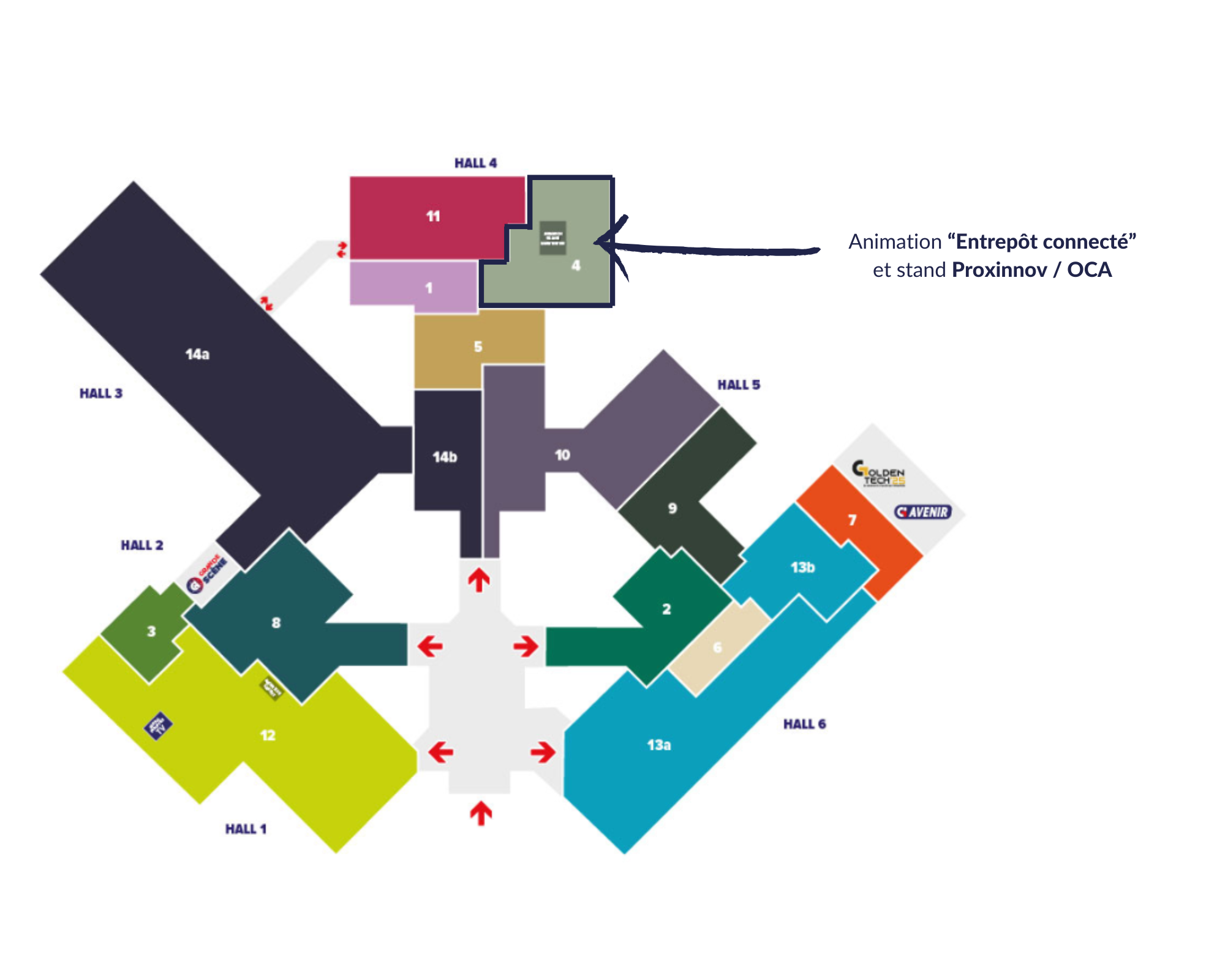

OCA is delighted to announce its participation in the 2025 edition of Global Industrie, to be held in Lyon from March 11 to 14. This year, we will be present in the handling, logistics, storage and lifting village, hosted by Proxinnov.

For the first time, Global Industrie is featuring a section dedicated to innovative solutions for supply chain optimization. The aim is to offer a range of 4.0 solutions to manufacturers wishing to reduce logistics-related costs, boost productivity and anticipate market fluctuations.

In this context, OCA will be presenting its latest-generation conveyor and taking part in a unique “Connected Warehouse” animation in Hall 4, Stand 4M223. This device will stand alongside other cutting-edge technologies such as autonomous mobile robots (AMR), cobots, machine vision systems and other ergonomic solutions. Meet our experts in Hall 4, stand No. 4Q211, shared with Proxinnov. We'll be there to answer all your questions and help you optimize your handling solutions!

Dans ce cadre, OCA présentera son convoyeur dernière génération et participera à une animation inédite "Entrepôt connecté" Hall 4, Stand 4M223. Ce dispositif se trouvera aux côtés d'autres technologies de pointe telles que des robots mobiles autonomes (AMR), cobots, systèmes de vision industrielle et autres solutions ergonomiques. Retrouvez nos experts Hall 4, stand N°4Q211, partagé avec Proxinnov. Nous serons à votre disposition pour répondre à toutes vos questions et vous accompagner dans l'optimisation de vos solutions de manutention !

"Connected Warehouse” animation in the handling village (Hall 4, Stand 4M223)

Why visit OCA at the show?When you meet OCA at Global Industrie, alongside Proxinnov, you'll discover how overhead handling solutions can be integrated and effectively optimize robot activity in industry. Thanks to our 44 years of expertise, we design high-performance, flexible conveyor systems capable of improving the efficiency and precision of industrial processes. In partnership with a wide range of players, we put forward innovative technologies that meet the challenges of the factory of the future. Don't miss this opportunity to explore concrete solutions for successful automated handling in your industry!

Practical info

📅 Dates: March 11.14, 2025

🚩Location: EUREXPO LYON, Boulevard de l'Europe, F 69680 Chassieu

📍Connected warehouse animation: Hall 4, Stand 4M223

To discuss our overhead handling solutions: Hall 4, Stand 4Q211

🎫 Create my free visitor badge